Machine Vision: Revolutionizing Industries with Intelligent Imaging

Introduction to Machine Vision

Machine vision is a technology that enables computers to interpret and analyze visual information from the world. It involves capturing images or videos through cameras, then processing and understanding the data using advanced algorithms. This technology is crucial in automating inspection, quality control, and guidance in various industrial applications. By mimicking human vision, machine vision systems can identify defects, read labels, and measure components with high precision and speed. Its integration into manufacturing, healthcare, automotive, and robotics has transformed traditional processes, increasing efficiency and accuracy. As AI and machine learning continue to advance, machine vision's capabilities expand, offering smarter, faster, and more reliable solutions. This innovation is shaping the future of automation, making industries more productive and competitive globally.

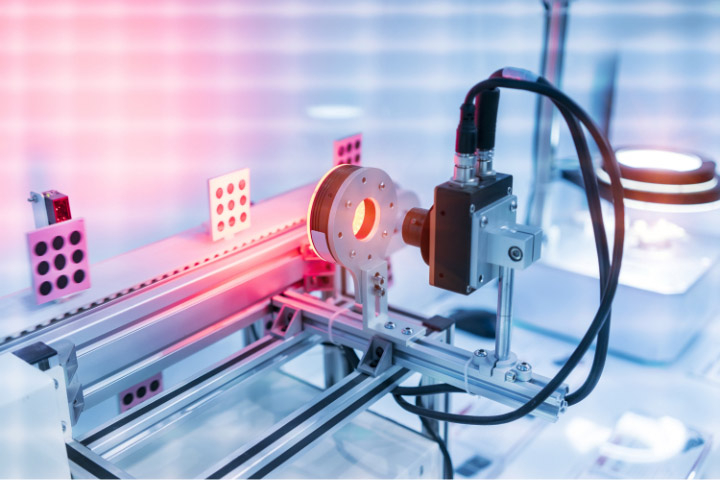

Core Components of Machine Vision Systems

A typical machine vision system consists of several essential components that work together to achieve accurate visual analysis. The primary element is the camera, which captures high-quality images or videos of objects or scenes. Lighting is also vital, ensuring the target is illuminated uniformly for clear imaging. Image processing hardware, such as frame grabbers and processors, converts raw data into digital images for analysis. Advanced software algorithms then interpret these images, detecting features, patterns, or defects. Additionally, actuators and controllers execute decisions based on the processed data, such as sorting items or guiding robotic arms. The integration of these components creates a seamless system capable of real-time inspection and decision-making, making machine vision invaluable in high-speed manufacturing lines and complex automation processes.

Applications Across Industries

Machine vision finds widespread application across diverse industries, revolutionizing traditional workflows. In manufacturing, it performs quality inspections, ensuring products meet strict standards by detecting defects, misalignments, or inconsistencies. In automotive, machine vision guides autonomous vehicles, enabling obstacle detection and navigation. The healthcare sector benefits through medical imaging analysis, aiding in accurate diagnoses and automated pathology. Retail and logistics utilize machine vision for inventory management, barcode reading, and automated checkout systems. Agriculture employs it for crop monitoring and sorting, optimizing yields. Robotics leverage machine vision for precise manipulation and navigation in complex environments. This versatility demonstrates how machine vision enhances efficiency, safety, and accuracy, making it an indispensable tool for modern industry and innovation.

Future Trends and Challenges

The future of machine vision is promising, driven by advancements in AI, deep learning, and sensor technology. Emerging trends include more intelligent systems capable of contextual understanding, enabling better decision-making. Edge computing will allow real-time processing directly on devices, reducing latency and dependency on cloud systems. Moreover, the development of more affordable and compact sensors democratizes access to machine vision technology for small and medium-sized enterprises. However, challenges remain, such as handling complex environments with variable lighting and occlusions, ensuring data security, and managing large data volumes. Privacy concerns and the need for standardized protocols also pose hurdles. Overcoming these challenges will require ongoing research and collaboration, ensuring machine vision continues to evolve as a powerful tool for automation, safety, and innovation in diverse fields.

Source: https://www.marketresearchfuture.com/reports/machine-vision-market-1510

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness