How Naishi's Trunnion Mounted Ball Valve Factory Extends Valve Lifespan?

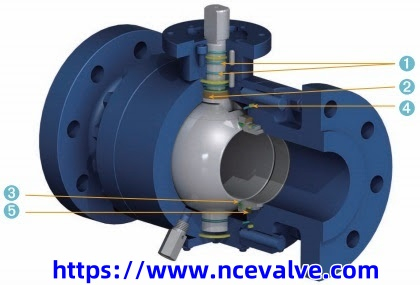

In the global landscape of industrial valve manufacturing, Naishi, a renowned Trunnion Mounted Ball Valve Factory, stands as a representation of precision engineering and dependable performance. Its fully welded trunnion mounted valves are developed for complex environments in oil, gas, and petrochemical systems where high-pressure resistance, long-term durability, and sealing integrity are indispensable. Every valve reflects the balance of advanced machining, meticulous design, and disciplined production, forming a foundation of trust between product capability and industrial necessity.

The engineering excellence behind these valves originates in controlled manufacturing processes that unite technology and craftsmanship. Within the production line, CNC equipment, robotic welding systems, and automated finishing tools work in concert to achieve dimensional consistency and structural balance. Each trunnion, body, and sealing surface is aligned to reduce friction and maintain uniform torque, enabling stable operation across prolonged service cycles. Digital measurement feedback and in-process inspection enable precise verification of machining parameters, which helps maintain predictable outcomes under variable operating conditions.

Quality assurance forms the central axis of the production framework, with layered inspection procedures designed to detect variation at the earliest stage. Raw materials undergo certification and metallurgical analysis, while component machining follows strict dimensional checks and hardness verification. Assembly is accompanied by pressure evaluation through hydrostatic and pneumatic simulations, and final acceptance testing records performance data for traceability. This systematic approach ensures each finished unit meets recognized international standards and preserves operational integrity in demanding service environments.

Beyond core production controls, research and development drive incremental improvements that respond to field feedback and simulation data. Engineers analyze stress distribution and flow characteristics to refine geometry and material selection, while endurance evaluation identifies opportunities for enhanced wear resistance. The application of predictive maintenance tools and intelligent monitoring contributes to reduced unscheduled downtime, allowing operators to plan interventions based on condition data rather than fixed schedules. This shift toward predictive reliability improves lifecycle economics while supporting operational safety.

Sustainability considerations also shape the manufacturing strategy, with workflow optimization and energy-efficient equipment reducing material waste and environmental footprint. Material choices emphasize longevity and corrosion resistance, which in turn minimize replacement frequency and associated resource consumption. Continuous improvement cycles focus on tool-life extension, process yield enhancement, and reduction of consumables, aligning production goals with responsible resource use. Through these measures, the factory embeds operational value with environmental stewardship.

As a distinguished Trunnion Mounted Ball Valve Factory, Naishi continues to uphold a heritage of precision, safety, and consistency in every valve produced. To review the fully welded trunnion mounted valve series and assess product specifications, visit https://www.ncevalve.com/product/fully-welded-ball-valve-1/fully-welded-trunnion-mounted-valve.html

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness